Research

Our research is focused on dynamic modelling and trajectory planning for mechatronic and robotic systems, collaborative robotics, mobile robotics and artistic robotic painting.

Dynamic modelling and trajectory planning

Trajectory planning for vibration reduction

Trajectory planning is a fundamental problem in robotics. Several approaches for trajectory planning have been investigated in the literature with the aim of enhancing productivity or other performance figures. Possible choices are for example the minimization of the energy consumption or of the execution time. Another interesting field of application of trajectory planning is the reduction of motion-induced oscillations. Indeed, robotic applications usually require smooth and jerk-limited trajectories during the prescribed task, to extend actuators lifetime, prevent mechanical damages and improve motion accuracy. We implemented an optimization method for the planning of smooth trajectories based on a cost function composed of a term proportional to the total execution time, and one term proportional to the squared jerk along the trajectory.

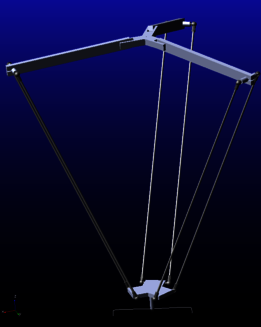

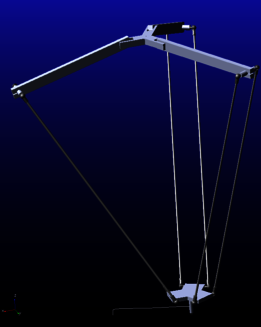

Energy efficiency in parallel robots

Energy efficiency is a challenging and relevant research field in modern manufacturing industries, where robotic systems play an essential role in the automation of several industrial operations. Different solutions and optimization methods to achieve energy efficiency in automatic machines and robots are studied. We proposed a strategy that leverages the task placement, the execution time, and the length of the robot lower arms to minimize the energy consumption for the execution of a predefined high-speed pick-and-place operation. The results of extensive numerical simulations show that the proposed strategy provides notable improvements in the energy efficiency of the parallel robot, with respect to alternative approaches.

Collaborative robotics

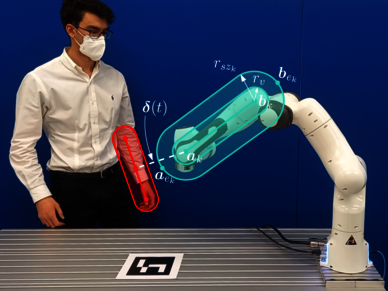

Online scaling of dynamic safety zones

In the context of Industry 4.0, collaborative robotics refers to the integration of robots into modern manufacturing processes in a way that allows for safe human-robot interaction. This technology enables human workers to operate alongside robots without the need for physical barriers, improving efficiency and productivity while maintaining a safe work environment. We explored and experimentally compared the effectiveness of robot-stopping approaches based on the speed and separation monitoring for improving fluency in collaborative robotics. In the compared approaches, a supervisory controller checks the distance between the bounding volumes enclosing human operator and robot and prevents potential collisions by determining the robot’s stop time and triggering a stop trajectory if necessary. The experimental results showed that scaling online the dynamic safety zones is beneficial for improving quantitative fluency metrics in collaborative robotics, demonstrating significant statistical differences with respect to alternative approaches based on the linear search of the best stop time, and on the implementation of the ISO/TS 15,066.

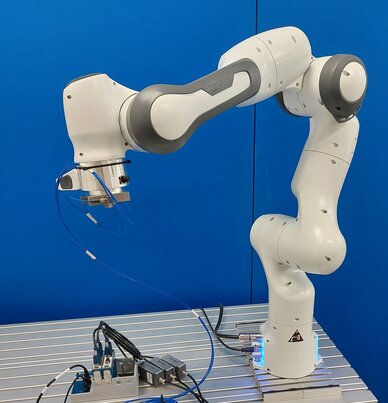

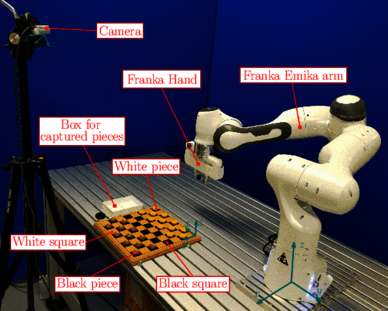

Playing Checkers with a collaborative robot

In the last years, collaborative robotics has been increasingly adopted in the manufacturing industry to allow machines and humans to work and interact in a shared space for a common task, while still ensuring human safety. However, collaborative robotics is not a privilege of the industrial sector, but it has been applied also for entertainment purposes thanks to the development of proper AI algorithms. We developed a collaborative robotics system for interactively play Italian checkers based on a Franka Emika manipulator and a vision system. The system is able to acquire the game state using a camera, select the best move among all possible ones through a decision-making algorithm, and physically manipulate the game pieces on the board performing pick-and-place operations. Minimum-time trajectories are optimized online for each pick-and-place operation of the robot, so as to make the game more fluent and interactive, while meeting the kinematic constraints of the manipulator.

Mobile robotics

Autonomous navigation and 3D mapping

Mobile robotics in agriculture